- Ahead of the times: In 1973, Opel introduced seat belts as standard across the range, three years before they became mandatory

- Start 1968: Opel Kadett, Admiral and Diplomat already available with front seat belts

- Comfortable: Omega 1986 first car with height-adjustable belts as standard

- Fine-tuned: New Astra Electric with further developed “belt anti-lock braking system”

The adaptively controlled restraint system uses sensors to recognise the severity of the accident and optimally adapts the belt force to the course of the crash. A plus in safety that can make all the difference. Despite all the airbags and assistance systems: “The seat belt is still the most important lifesaver in the car,” says Peter Schüßler, Manager of Passive Restraint Systems at Opel in Rüsselsheim. And the most important of all safety features is celebrating an even-number anniversary this summer: 50 years ago, in 1973, Opel began to install three-point belt systems with practical one-hand operation as standard in all models – and that three years prior to wearing seat belts became compulsory in Germany. A lot has happened in 50 years: an average of 15 metres of seat belts are installed in every Opel model. In total, after five decades, this results in around 750 million metres of seat belt webbing. This corresponds to 18 circumnavigations of the equator.

Safety comes first at Opel: the seat belt as a lifesaver

As early as the 1960s, Opel engineers were testing seat belts as a life-saving restraint system in cars. As early as April 1968, the Opel Kadett, Admiral and Diplomat, among others, could be ordered with front seat belts. The classic Manta A coupé followed in October 1970. The Opel lifesaver was also available as standard in the sporty models – for example in the Kadett B Rallye from 1967 and in the Commodore A GS a year later.

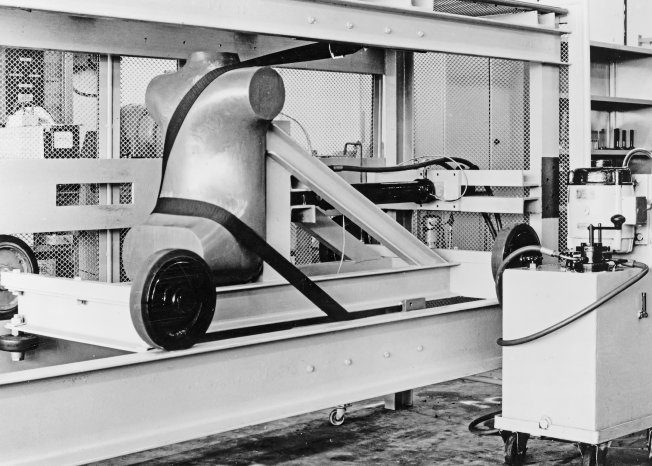

At the same time, Opel actively campaigned for the acceptance of seat belts early on and thus assumed a pioneering role. In 1969, Opel engineers demonstrated the results of their accident research programme to representatives of the media at the Dudenhofen Test Centre. The most important message: more than half of all accident victims could still be alive if they had worn seat belts. At the beginning of 1972, Opel’s management sent a letter to all employees, asking them to wear their seat belts – and offered all employees discounted belts for retrofitting. The offer proved hugely popular with 12,000 sets being provided within a very short time.

Significance recognised early on

The general public were somewhat more reluctant to accept the seat belt as an indispensable part of vehicle safety. Millions of people initially refused to “buckle up” when it became compulsory to wear seat belts as of January 1, 1976. At that time, many considered it to be too cumbersome to wear a seat belt. Especially when the car was used by different family members and the seat belt had to be adjusted in each case. This problem was soon solved by the automatic seat belt retractor. For a long time, however, there seemed to be no cure for various prejudices such as: The belt curtails personal freedom, and its safety effect is questionable. But the concerns were silenced when the number of road fatalities began to fall.

Simultaneously, the safety specialists were constantly improving the systems. In 1986, the Opel Omega was the first car in the world to offer height-adjustable seat belts at the front and rear seats as standard. In 1991, Opel presented the belt tensioner in the Astra F, followed by the full-size airbag and active safety systems such as the anti-lock braking system and the electronic stability programme.

Airbags, in particular, further reduce the risk of injury significantly – assuming that the driver and passengers are actually buckled up. One system restrains the body in the event of a collision, the other cushions the impact. The seat belt absorbs around two-thirds of the energy of an impact. The first belt force limiters were used from the 2000s to avoid peak loads. Other improvements increase comfort, such as the electric seat belt feeder in convertibles.

Crucial millimetres: The collapsible steering column

The Opel engineers identified another key factor for more safety back in the 1960s: the safety steering column. Preventing the steering wheel and column from penetrating the passenger compartment is still one of the starting points of the safety strategy. In the event of an impact, the steering column collapses slightly. In this way, the system, in combination with the seat belt and airbag, enables a dynamic crushable distance of up to 100 millimetres – crucial millimetres that minimise the risk of injury.

The adaptive belt force limiter now installed in the Opel Astra Electric has an even more refined “anti-lock braking system” for the belt. “The belt force is electronically controlled during the course of the impact,” the specialists explain. “In order to measure the biomechanical load acting on the chest, four sensors are installed in the THOR crash test dummy.” In earlier versions, only single measurements were possible. This increase in sensitivity was made possible by the latest generation of crash test dummies, which have been in use since 2020.

Sensors galore: New dummies provide crucial insights

The development of the safety belt is inextricably linked to the further development of the intelligent high-tech dummies that are used in tests to simulate the effects of an impact on the human body before a safety system is approved for series production. The youngest generation is known as THOR. The abbreviation stands for “Test device for Human Occupant Restraint”. Equipped with over 120 sensors, THOR electronically senses and communicates what happens to it in the event of an impact. With this dummy’s help, the adaptive belt force limiter was developed, which was first used in the Opel Mokka and now in the Astra. It is another milestone in the decades-long development of passive safety features. And the possibilities are far from exhausted.

New challenges posed by automated driving

From 2026, for example, consumer protection tests are to evaluate injury values that consider the more fragile bone structure of senior citizens. The team in Rüsselsheim also has its sights firmly set on the more distant future: Automated driving will alter a lot completely. Above all, because vehicle occupants will no longer necessarily sit facing forwards, but may face each other. And some could even be lying down. Seat belts could be fully integrated into the seats. “We are already working intensively on what this means in detail for the restraint systems,” explains Peter Schüßler. With automated driving, the success story of seat belts, which has lasted for five decades, will then enter a new era of saving lives.